Common PCB Assembly Defects and How to Fix Them

Do you have any knowledge about printed circuit boards? Are you aware of the various PCB assembly defects? Do you have a solution to fix them? If no is your answer, then you can contact the best electricians in Stanton to fix PCB assembly defects in no time. Any electronic device cannot function without printed circuit boards. In other words, these boards are the lifeline of electronic devices. Be it your mobile phone, iron, speakers, coffee makers, mixers, etc., almost every single electric device operates today because of the printed circuit board inbuilt in them. So, if you are facing any kind of issue with your circuit board, immediately book electronic circuit board repair services in San Diego.

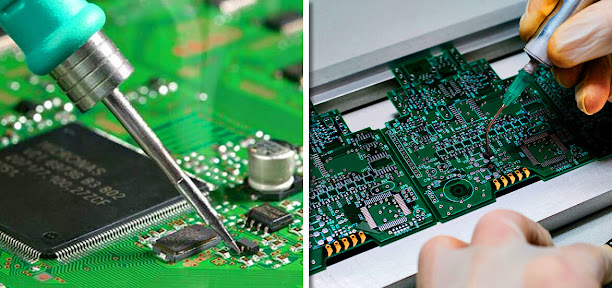

Printed circuit board (PCB) assembly means bringing together various parts of a device and then assembling them with other essential parts, such as components, resistors, etc. These assembling is done to make these parts perform the function they are intended to do. The right technology, along with raw materials and components, completes the assembling process successfully.

Different companies follow different technologies. The assembling process differs from one circuit board to another. Likewise, the choice of technology even differs. PCBA is the major step in PCB manufacturing. Any defect in this process leads to the poor functioning of these boards. When you understand the defects of PCBA, its root cause, and the way to fix them, you can improve the process of assembling.

Printed circuit board (PCB) assembly means bringing together various parts of a device and then assembling them with other essential parts, such as components, resistors, etc. These assembling is done to make these parts perform the function they are intended to do. The right technology, along with raw materials and components, completes the assembling process successfully.

Different companies follow different technologies. The assembling process differs from one circuit board to another. Likewise, the choice of technology even differs. PCBA is the major step in PCB manufacturing. Any defect in this process leads to the poor functioning of these boards. When you understand the defects of PCBA, its root cause, and the way to fix them, you can improve the process of assembling.

Common Defects In PCB Assembly And The Ways To Fix Them

Working with faulty PCBs is frustrating and also takes more time. The continuous breakdown in the circuit board ruins your work. A PCB must work efficiently. Continuous failures lead to spending more cash and time on their repairs. It even decreases productivity. So, to maintain a proper PCB, you must have adequate knowledge to avoid manufacturing low-quality circuit boards. High-quality boards would be long-lasting and even would add to productivity.

You have invested a lump sum amount of money on printed circuit boards, so it’s difficult to get new PCBs every time a circuit board goes bad. The best solution is to repair your faulty circuit boards. But it’s crucial to seek help from professionals who have enough experience in this field and have worked on PCB-related issues. They can solve all your PCB-related issues at very nominal charges. Let’s have a look at the various PCB assembly defects and how to fix them.

1. Copper Deposition

There are several important holes in the electric circuit board which allow electricity to flow through them from one part to another part of the board. But before electroplating, the circuit board is made conductive by copper deposition from top to bottom.

The problems with copper deposition give rise to plating voids. Hence, the walls of the holes are not properly coated, affecting the passage of electricity by the holes. It can also occur due to many reasons such as the formation of air bubbles, the occurrence of corrosion, contamination of the material. So to avoid defects caused by material contamination or air bubbles, you can clean the material property before drilling it. You may even avoid other defects by following the advice of the manufacturer. You may even hire professionals to give you proper guidance for your PCB. If you are searching for circuit board repair services in San Diego, you may easily contact them through their website to avail services from them.

2. Component Shift

It is the most common defect faced by PCB assemblers. The component shift means wrong parts get joined together. This often occurs during reflow as parts move and shift over the molten hot solder. Some parts misalign themselves, causing defects. It occurs due to tension existing on the molten solder surface. Some other factors also cause component shifts, such as bend leads, poor solder placement, and fast vibrations in the conveyors.

So, you should take measures to get away with it. The manufacturer should maintain the right humidity and have a proper temperature. However, the manufacturer should ensure minimum movement. Many professional teams are providing a better understanding of the fixing of components. You can even check on Google for their assistance. Contact professionals for control board repair services in San Diego and get the best solution for your PCB problems. They would assist you and give you the required information.

3. Power Failure

Power failure can be caused to a single or all the parts of the board. It arises as some parts of the PCB were exposed to higher voltage heat than normal, causing the part to explode. There can also be trace failure causing shorts somewhere? The best solution for this defect is a power meter. Yes, you heard it correctly. A power meter helps detect the conductivity of various components in and out. Every professional team has a power or voltage meter to diagnose problems with the components. You must take help from the best electricians to get your damage repaired. They would either replace or reset the components.

4. Physical Damage

Physical damage to the PCB can be scary either during the SMT manufacturing process or due to the wrong handling of the board. The main cause for PCB is dropping the boards during the prototyping phase. The physical damage done to the circuit boards or the inner components can’t be easily located or repaired. Replacing the old PCB with a new one is the best solution to get away with this defect.

Besides this, you can easily identify the default design due to continuous failures after regular use. It can also happen due to the cheap quality materials used for the components by the manufacturer. The appropriate solution for an improper board is to completely replace it by visiting any licensed repair center for circuit board repair services in San Diego.

Working with faulty PCBs is frustrating and also takes more time. The continuous breakdown in the circuit board ruins your work. A PCB must work efficiently. Continuous failures lead to spending more cash and time on their repairs. It even decreases productivity. So, to maintain a proper PCB, you must have adequate knowledge to avoid manufacturing low-quality circuit boards. High-quality boards would be long-lasting and even would add to productivity.

You have invested a lump sum amount of money on printed circuit boards, so it’s difficult to get new PCBs every time a circuit board goes bad. The best solution is to repair your faulty circuit boards. But it’s crucial to seek help from professionals who have enough experience in this field and have worked on PCB-related issues. They can solve all your PCB-related issues at very nominal charges. Let’s have a look at the various PCB assembly defects and how to fix them.

1. Copper Deposition

There are several important holes in the electric circuit board which allow electricity to flow through them from one part to another part of the board. But before electroplating, the circuit board is made conductive by copper deposition from top to bottom.

The problems with copper deposition give rise to plating voids. Hence, the walls of the holes are not properly coated, affecting the passage of electricity by the holes. It can also occur due to many reasons such as the formation of air bubbles, the occurrence of corrosion, contamination of the material. So to avoid defects caused by material contamination or air bubbles, you can clean the material property before drilling it. You may even avoid other defects by following the advice of the manufacturer. You may even hire professionals to give you proper guidance for your PCB. If you are searching for circuit board repair services in San Diego, you may easily contact them through their website to avail services from them.

2. Component Shift

It is the most common defect faced by PCB assemblers. The component shift means wrong parts get joined together. This often occurs during reflow as parts move and shift over the molten hot solder. Some parts misalign themselves, causing defects. It occurs due to tension existing on the molten solder surface. Some other factors also cause component shifts, such as bend leads, poor solder placement, and fast vibrations in the conveyors.

So, you should take measures to get away with it. The manufacturer should maintain the right humidity and have a proper temperature. However, the manufacturer should ensure minimum movement. Many professional teams are providing a better understanding of the fixing of components. You can even check on Google for their assistance. Contact professionals for control board repair services in San Diego and get the best solution for your PCB problems. They would assist you and give you the required information.

3. Power Failure

Power failure can be caused to a single or all the parts of the board. It arises as some parts of the PCB were exposed to higher voltage heat than normal, causing the part to explode. There can also be trace failure causing shorts somewhere? The best solution for this defect is a power meter. Yes, you heard it correctly. A power meter helps detect the conductivity of various components in and out. Every professional team has a power or voltage meter to diagnose problems with the components. You must take help from the best electricians to get your damage repaired. They would either replace or reset the components.

4. Physical Damage

Physical damage to the PCB can be scary either during the SMT manufacturing process or due to the wrong handling of the board. The main cause for PCB is dropping the boards during the prototyping phase. The physical damage done to the circuit boards or the inner components can’t be easily located or repaired. Replacing the old PCB with a new one is the best solution to get away with this defect.

5. Improper Design

Improper or poor design of the circuit board can lead to many failures. The electronic device would not function properly, leading to continuous on-off. This all happens because of the poor design of the printed circuit board. Often manufacturers cut the edges or corners of the board and even some components, which later causes trouble due to the poor construction of the board.Besides this, you can easily identify the default design due to continuous failures after regular use. It can also happen due to the cheap quality materials used for the components by the manufacturer. The appropriate solution for an improper board is to completely replace it by visiting any licensed repair center for circuit board repair services in San Diego.

.jpg)

Comments

Post a Comment